Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

Last Updated on December 28, 2022 by Charles Wilson

A lathe carrier is a piece accessory that clamps the workpiece to a lathe. They are commonly referred to as “lathe dogs.”

In addition, a lathe carrier is a clamp attached to a machine’s spindle to allow for rotary motion to be relayed to the workpiece.

Often, a lathe carrier is used with a drive plate if the materials they are working on have an active and dead center.

When centers do not provide enough friction, this scenario is when a lathe carrier is needed.

Clamping the lathe carrier to the workpiece allows the machine’s spindle to have a rotational force.

Key Takeaways

- A lathe dog is also called a lathe carrier.

- A lathe dog is usually used in industrial and machine tools accessories

- A lathe dog clamps the workpiece for smooth and even turning

- There are three different types of lathe dogs, straight tail, standard bent tail, and standard.

- A lathe carrier is often made with high-grade iron

- A lathe carrier is made of durable and rigid construction for optimal strength

What Is the Purpose of Using a Lathe Dog?

The purpose of a lathe dog is to cause materials to rotate.

As I’ve mentioned, if a material or an object is held between a dead and a live center, the force of friction needed is NOT enough to rotate the material.

But a lathe dog can be clamped to a machine’s spindle to provide rotary motion when turning metals when chucks can’t.

What Are the Three Types of Lathe Carriers

These accessories have different types to suit a machinist’s needs. Each type is made of rigid construction to ensure a finer workpiece result.

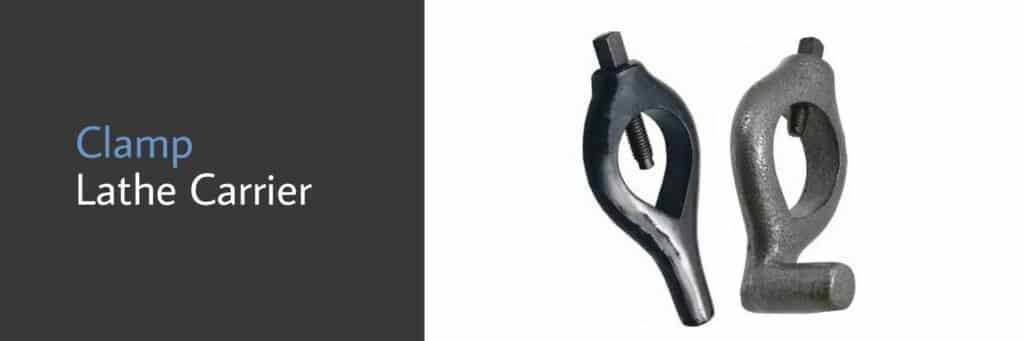

Clamp Lathe Carrier

One type of lathe dog is a clamp lathe dog.

It is specially designed to hold non-cylindrical shaped materials, such as rectangular, square, and other odd-shaped materials.

Most of the time, they are used for clamping abnormally-shaped objects while reducing the spindle’s speed to make it safe for work.

Straight Tail Lathe Carrier

This device rotates by catching a stud on the drive plate.

When this type of device is used for a workpiece, it usually rests on top of the faceplate, providing the rotational force.

This device is safer because it is straight to the lathe dog’s center. As a result, there’s a reduced chance of a workpiece being imbalanced.

Standard Bent Tail Lathe Carrier

This type of lathe carrier is often used when turning round and cylindrical-shaped pieces. It works by attaching its tail to the slots of a chuck or the driving faceplate.

The only problem with this type of device is its ability to crow off the center of the workpiece.

This issue happens because the rotary motion is focused on the side of the straight-tail lathe carrier, which can lead to inaccurate cuts.

Furthermore, this lathe carrier device poses a great danger if not used properly. It is why most experienced machinists only use the standard bent tail for their workpieces.

Final Thoughts

Lathe carriers often have a bad rep, for a few metal turners are still using them.

While they have certainly aged, they are still useful when two centers are being worked on and the object needs to rotate.

Driven by its tail, work commences if all you need is rotation force when other clamps don’t work.