Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

Choosing the best metal lathe for your projects can be challenging. It’s essential to have a clear understanding of what you need and the type of work you’ll be doing. Consider the kinds of projects you plan to create, the machine’s versatility, and other key factors. Simply having the budget isn’t enough—you need to make an informed decision to find the right tool for the job.

Metalworking is a process that creates satisfying results out of the most ordinary materials. It is not only for professionals either! You can do metalworking as a hobby or for academic purposes teaching students.

Regardless of your goal, the best way to turn metal is with a metal lathe.

Here I will go through different metal lathe types and what they do and help you pick the best one to start working on your due projects.

So let’s jump in with a quick chart of the top metal lathes:

Last update on 2025-04-24 / Images from Amazon Product Advertising API

Best Metal Lathes Ranked

Enough of introduction and waiting. Now let’s jump onto the main part of this article. I am bringing to the table the top-notch metal lathes you could get depending on your needs out there in the market. Here you go.

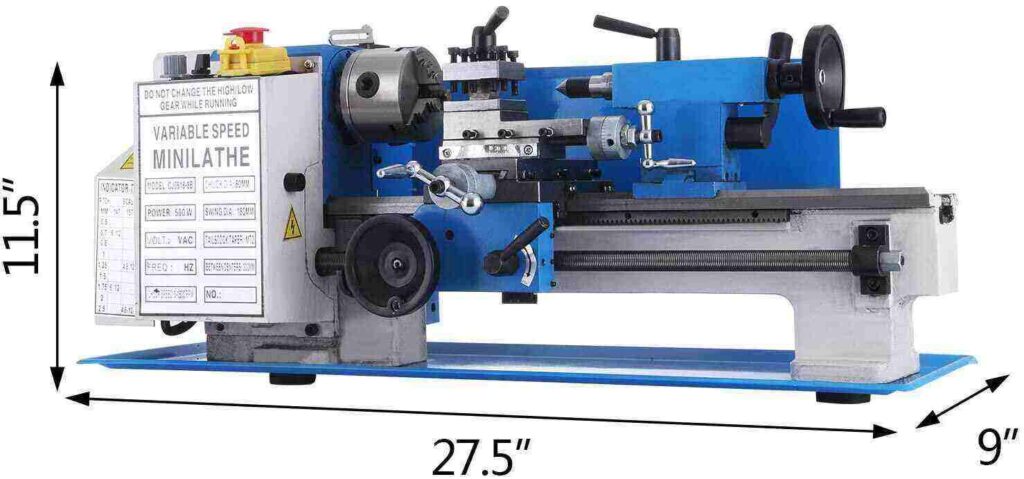

Overall Best Metal Lathe: BestEquip 7 x 14

- 7″ swing and 14″ between centers

- Motor: 550W DC Single Phase

- Spindle Speed: 0-2250 RPM

- Infinitely Variable Speeds

- Swing Over Cross Slide: 110mm

- Tailstock Taper: Mt2

- Spindle Taper: Mt3

- Cross Slide Travel: 65mm(2.53″)

- Chuck Diameter: 100mm(3.94″)

- Inch Thread: 12-52 T.P.I

- Spindle Accuracy: 0.01mm

- Weight: 101.9 lbs

- Warranty: Contact seller

When working with metals, your best ally is a tool capable of working with them. This tool needs a powerful energy source, constant rotations per minute, and variable speed.

Herein, the BestEquip lathe meets all of those requirements effectively. It features a 0.75 horsepower motor working at 550W and 110 volts.

The motor is powerful enough to distribute the energy across the machine making it very easy to work the metals. For higher versatility, you can change the working speed from 50 to 2500 rotations per minute with its variable-speed motor.

The motor and its many benefits allow you to work on different materials. Of course, the main purpose of this tool is to work with metals, but you can use it for wood and jade as well as other materials.

That versatility makes this item a reliable tool for experts and amateurs. For example, you can use it in the laboratory, in particular workshops, and for educational purposes. It also features a unique lathe chuck with adjustable jaws.

This lathe jaw chuck allows the machine to hold asymmetrical materials while also enabling a precise configuration for cylindrical materials as well.

The machine’s pieces are easy to adjust, and you can adjust them to work on different projects. This particular lathe is one of the best metal lathes for machinists who like accurate results.

For the tool’s maintenance, it takes a couple of simple steps to follow. You should clean every surface with a commercial solvent. Nonetheless, products like thinner or gasoline could damage the product’s functionality.

This is why you have to follow the maintenance instructions strictly.

Pros

suitable for professional and amateur purposes

Cons

Best Metal Lathe Runner-Up: Erie Tools 7 x 14

- 7″ swing and 14″ between centers

- Motor: 400 W, 0.53HP, 120 V, 60 Hz

- Variable-Speed Motor

- Spindle Accuracy: 0.0004 in. (0.01 mm)

- Thread Range: 12 to 52 TPI

- Spindle Taper: MT3

- Tailstock Taper: MT2

- Chuck Diameter: 4 in. (80 mm)

- Spindle Bore: 0.79 in (20 mm)

- Cross Slide Travel: 2.56 in. (65 mm)

- Top Slide Travel: 1.38 in. (35 mm)

- Weight: 104.2 lbs

- Warranty: 1 Year

The product’s efficiency is possible because of its energy source. It features a single-phase motor with different speeds.

You can adjust the speeds up to 2500 rotations per minute capacity. This speed produces quality in both rotational directions, whether forward or reverse.

It also features many pieces that support the lathe during its operations. These pieces are the chuck, a five-piece cutter set, the internal jaws for the chuck as well as the external jaws, a very helpful 11 feed rate gears, and of course, the manual for the owner which provides the tool’s information.

It is because of all these elements that this machine is very effective. Not only does it provide an incredible experience for the user, but also a productive performance not many other tools can deliver.

For that reason, this lathe is suitable for drilling, cutting, and turning a diverse amount of materials. These materials are metals naturally, but it also works great with wood and even plastic.

Regardless of the material, the lathe will deliver smooth and quality results.

In case you need to adjust the RPMs, you can always check out the digital readout. It has all the information you need, and it is very easy to read which allows everyone to use it regardless of their experience.

Overall, this is a very efficient tool at an accessible price.

Pros

Pros

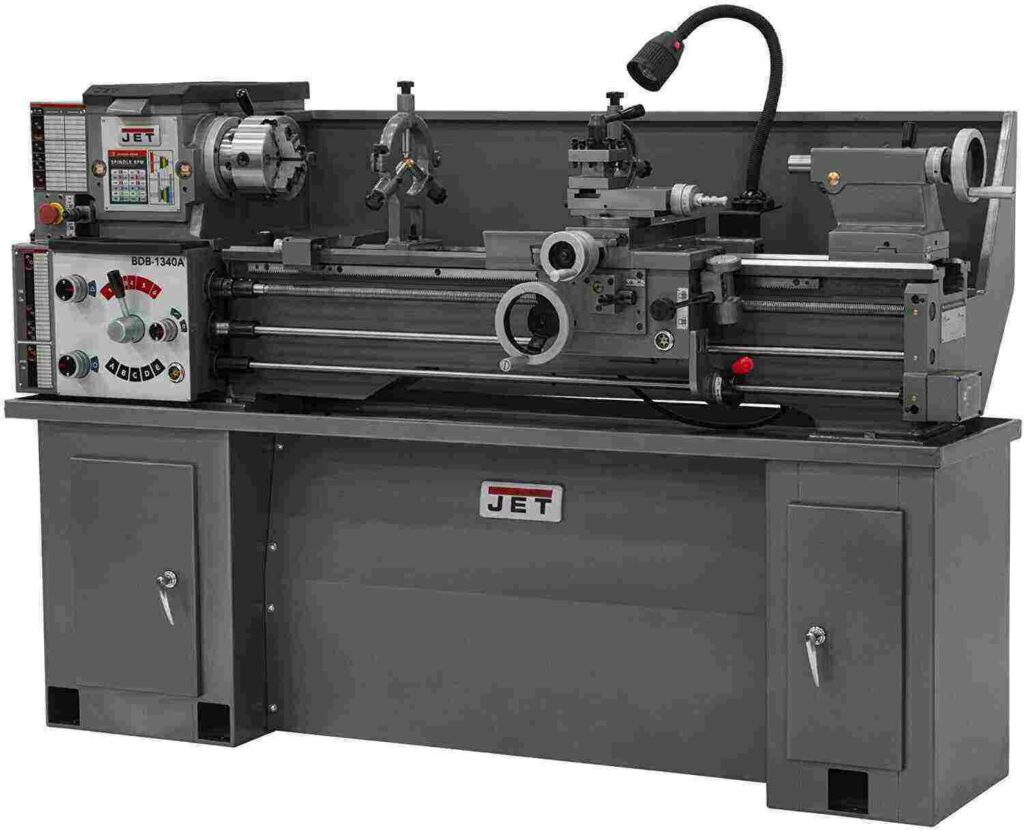

Best Full-Sized Metal Lathe: Jet BDB-1340A

- 13″ Swing and 40″ between centers

- Motor: 2 HP, 230V, 1Ph

- Swing Through Gap (In.): 18-3/4

- Length of Gap (In.): 8

- Spindle speeds: 12; 60 to 1,240 RPM

- Spindle Taper with Sleeve: MT-5 (MT-3)

- Taper in Tailstock Spindle: MT-3

- Carriage Travel (In.: )35

- Width of Bed (In.): 7-3/8

- Low voltage motor controls

- Weight: 1175 lbs

- Warranty: Limited 2 Year (Mechanical), Limited 1 Year (Electrical)

This metal lathe is a powerful tool. The lathe’s motor is the most important element, and sometimes metal lathes do not have the motor you need.

This problem can cause many incidents in a chain reaction.

A weak motor for working metal is not ideal, and it becomes an unpleasant experience quickly. Its weakness translates into a deficient performance from the machine.

This creates vibrations or noises and it ruins the total experience.

However, there are options to topple those problems. A great example of that is the Jet 321360A. With the two horsepower motor capacity, you will complete your many projects without functionality issues.

The motor produces enough energy and distributes it successfully across the machine.

Naturally, every machine needs the right pieces to withstand the power. In order to do that, this metal lathe includes a suitable gearbox.

This gearbox features helical cutting gear that reduces unpleasant factors, like noise. By keeping the noise low, it allows you to have full concentration which is necessary to get the best result possible.

Like any other tool, this machine seeks to assist you for an extended amount of time. To achieve that, it features bigger splash guards that maintain the machine’s integrity intact.

You also get a durable tool because of its resistant building materials.

In case you want to do changes and adjustments, the gearbox allows you to have a faster and easier changing process. It is a quality machine with a solid performance in different types of projects.

Pros

Cons

Best Mini Metal Lathe: Grizzly G8688

- 7″ swing and 14″ between centers

- Motor: 3/4 HP, 110V, single-phase

- Speed range: 0-1100 (low) , 0-2500 (high) RPM

- Forward and reverse at all speeds

- Bore Size of Included Chuck: 16mm

- Spindle bore: 0.78″

- Spindle nose taper: MT #3

- Tailstock taper: MT #2

- Tailstock travel: 2-1/2″

- Cross-slide travel: 2-3/4″

- Maximum tool bit size: 5/16″

- Shipping weight: 90 lbs.

- Warranty: 1-year

But perhaps you are not looking for a big machine that takes up too much space.

Your projects do not require bulky and extravagant tools. Instead, you want a metal lathe that allows you to place it almost everywhere, especially if you are using it from the comfort of your home.

If that is the case, then let me tell you that this is probably the product you need.

While it is true that it does look small in comparison to other models, let’s not doubt its capabilities.

It is powered up by a capable 3/4 horsepower motor which provides the necessary energy for your projects. The motor is responsible for the multiple working speeds in this machine, and they have multiple ranges.

These speeds vary from 0 to 1100 rotations per minute at a low range, but it also features a higher range with speeds from 0 to 2500 rotations per minute.

The different speeds work great for both forward and reverse directions. This means you will acquire a versatile tool and more control over the metals in the machine.

Other specifications of this product are a 7-inch swing and a 12-inch distance from the center. It also features a dial indicator to keep track of the machine’s functionality and standard handwheels for better graduation.

As a final observation, I want to mention its weight. This tool weighs 74 pounds making it one of the metal lathes with lesser weight in this list.

The weight and the lathe’s size make this product worth considering.

You can get my full Grizzly G8688 review right here. That’s everything I know about this model and I hope it is well worth your time.

If you do have more of a budget, check out this awesome review of the Grizzly G0602 model. It’s a different one but you can see the differences before making any decision.

Pros

Cons

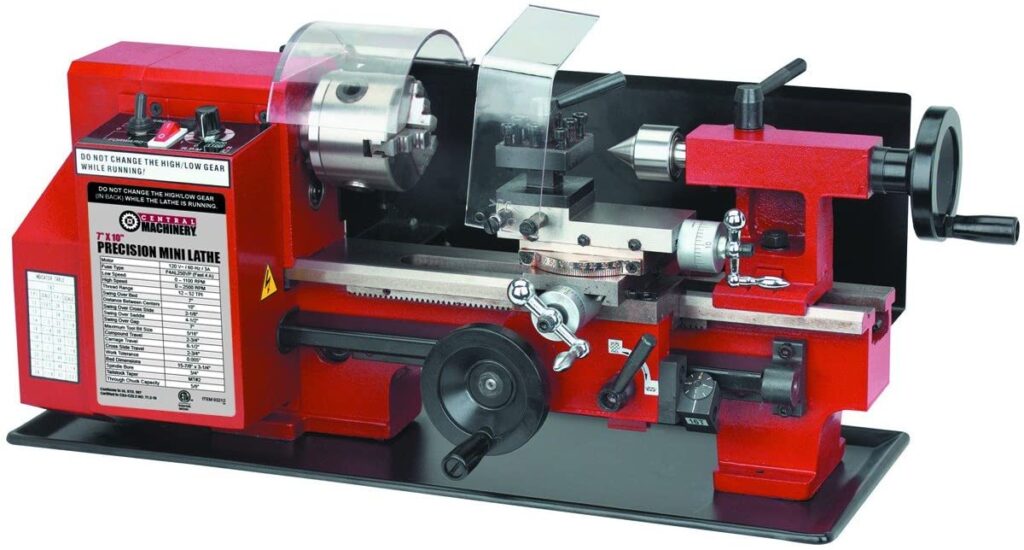

Best Beginner Metal Lathe: Central Machinery Precision Lathe

- 7″ swing and 10″ between centers

- Motor: 3/4 HP, 120V AC

- Speed Max: 0-2500 RPM

- Speed Min: 0-1100

- Tailstock taper: MT2

- Spindle Taper: MT2

- Thread Size: 12-52 TPI

- Automatic feed

- Weight: 87.05 lbs

- Warranty: 90 Days from the date of purchasing

When you are initiating your way into the metalworking field, you definitely need the proper tools to assist you.

Getting a professional heavyweight machine is not recommended for a machinist who’s new to metalworking, especially because they feature too many accessories that you won’t need in light projects.

On the other hand, buying an easy-to-use and cheap metal lathe is probably your best choice because it will allow you to work on easy projects while learning your way around the machine.

It features a 3/4 horsepower with a 2500 RPM maximum capacity which you can control through a knob successfully. The machine includes an automatic feed for better operations as well. Additionally, it features a chuck guard to keep it secured.

Thanks to the lathe’s great performance it allows you to turn, shape, and make bushings, prototypes, and design your own models.

However, setting up for this tool is not easy, and it could become an issue quickly.

To get it to work properly, it requires you to disassemble the pieces, like the carriage, compound, and cross slide to make a quick maintenance process and clean them up.

It is very important to follow the manual and the instructions clearly, especially when setting it up and its maintenance process.

Otherwise, if you make even a small mistake, your general experience will have unpleasant consequences like malfunctioning and a poor quality result.

Other than that, it is a good option to consider. You could put it under different applications as well, either in a workshop or in a lab environment.

Pros

Cons

Last update on 2025-04-24 / Images from Amazon Product Advertising API

Best Metal Lathe FAQs

Still have questions about buying the best metal lathe for your needs? Take our quick quiz and check out our FAQ section below.

What else should I Consider Before Choosing a Metal Lathe?

So, you finally decided to go ahead and buy a metal lathe, but the many options available on the market are confusing to sort out. After all, every model and brand offers different features, and each model seems suitable for your project, but this is not always the case.

Before you make any decision, you have to make sure the item you buy meets certain requirements.

These requirements not only make the product a great acquisition but will also provide you with a more pleasant experience while working.

Without further ado, let’s dive into the considerations you should have in mind before buying the metal lathe.

The Design

The machine’s design may seem like something not important, but that is far from the truth. Through its design, the lathe is capable of giving you very important information about what it can or can’t do.

The main highlight I get from the design is whether or not it is an easy machine to use.

I encounter two types of products in the market, one with an easy-to-understand design and another with a more complex design.

When you are starting your way as a machinist metal turner, you will need a user-friendly product that does not require high technical knowledge.

Sure, you can always learn and use more complex machines, but even the cheapest and simplest machines can produce great results sometimes.

For that reason, getting a product with a simple design is the best action to take as you learn your way around the lathe. The other option is, obviously, machines with a more complicated design.

Now, these tools are great for experienced users because they can benefit from all the advantages it offers.

A more complex machine allows you to add multiple tools to increase its performance, and you’ll produce a more quality result in the end.

For more on a lathe’s design, check out our post on parts of a lathe.

Lathe Structure

Another important element to consider is the machine’s structure. Ideally, the best metal lathe should have a solid structure with great support.

Not only will it provide a more comfortable machine to use, but it will also have better functionality by maintaining its positioning.

When the machine does not have a solid structure, it is likely that the user will encounter issues like vibrations, and loud noises and will produce results with poor quality.

For that reason, considering the machine’s structure is always an important thing to do. Look for tools with quality materials like steel, because they will offer you the stability not many products offer.

A solid tool produces quality results, a highly comfortable experience, and it also maintains the tool’s lifespan by reducing impact risks and other malfunctions.

Another great benefit of a great-quality structure is versatility. These metal lathes often have different applications like labs or home workshops, and that is possible because of the steel and materials in their structure.

Functionality

The machine’s functionality is another decisive factor to keep in mind. Of course, every brand out there will tell you their product is the best option, but remember, nobody knows what you need better than yourself.

If your job requires you to work with metals in particular, then all of the products in this review are a great option for you. However, if you work with a variety of materials, there are specific products that give you that possibility.

These machines are incredible to work on metals, but some of them have enough versatility to work on wood or other materials as well.

However, it is not only about the materials, but you have to consider its other applications too.

For instance, a good metal lathe will produce great results under certain circumstances, but a great machine delivers quality results in multiple scenarios.

Not only does it work at a professional level, but it is also ideal if you use it for educational purposes.

For all of those reasons, make sure you get the best metal lathe capable of operating in a wide variety of applications.

So all of these features are worth considering when you decide to buy a metal lathe. Every aspect of the tool, even if it seems minimal and unimportant, will determine your project’s success.

Every piece counts and every little detail is important for creating a pleasant working experience.

For more information, check out our metal lathe buying guide.

What Cutting Tools Do I Need for a Metal Lathe?

Metal lathes include all the pieces you need to have a good performance. Nonetheless, there are additional cutting tools that enhance your experience, and the main purpose of these tools is to produce the best result possible.

Among these tools you can find the following:

Boring Bar

A boring bar is a tool for metal and woodworking applications. Boring is a popular technique that focuses on building processes, and woodworkers continue to use that technique to this day, even though it dates back many decades.

For metalworking purposes, the boring bar is different from its woodworking counterpart. Check out our post on how to use a boring bar.

You can use this tool to create asymmetrical channels, but it works great to create circular holes. It all depends on which direction you are using it.

Drill Chuck

Drill chucks are capable of locking the materials to keep them in their place. Through the use of a drill chuck, the worker will have a comfortable operation without worrying about a soft grip.

This tool proves its worth by allowing you to have a successful working session. It also provides you with a satisfying and smoother result.

Parting Tool

More often than not, you will find, the material exceeds the size of the machine. Therefore, you cannot work on it as comfortably as you would want.

For these scenarios, the parting tool is a great problem solver. It allows you to cut those unnecessary pieces shortening the material and making it more suitable to control.

Knurling Tool

You can use this tool if you have the need to add knurling for your stock. It is an effective tool for knobs when you require a stronger and solid grip over the pieces.

Are there different Types of Lathes?

Yes, different lathes have different sizes, structures, and functionality. To help you decide which one is the best option for you, here is our post on the different lathe machine types.

Can the metal lathe work with other materials like wood?

Yes, they can work with different materials other than metals. However, this is not recommended. There are specific lathes for woodworking, and while the metal lathes can operate over wood, their main goal is to work with metals.

After all, the woodworking results will not have the same quality.

For a full discussion of this topic, check out my article all about turning wood on a metal lathe.

Who can use the metal lathe?

Students, professionals, DIY enthusiasts, and anyone interested in turning metals.

Thanks to their higher versatility, you can use these machines for diverse applications. These are especially great for professional gunsmiths at a highly demanding job.

On top of that, students can also use it for learning purposes.

Does a metal lathe require maintenance?

Yes, it does. Like any other tool that uses steel in its structure, the metal lathe requires maintenance to keep it in a good state. Proper maintenance is necessary if you want to keep away from issues like rust.

Nonetheless, you must use the right tools to maintain it and make sure you keep it from receiving unnecessary damage. If you do, it will definitely work for you for many years.

Is the metal lathe easy to use?

Most of them are easy to use. Obviously, if you are going to work on bigger and more complex projects, it will require certain knowledge and proper preparation to produce a quality result.

Check my basic guide to how to use a metal lathe.

What is a lathe spindle and how does it work?

Throughout this post, we’ve referenced spindles a lot. We talked about spindle speed, spindle taper, spindle accuracy, and spindle bore. If you’re wondering What is a Lathe Spindle and How Does It Work?, follow that link to learn more about lathe spindles.

Do I need extra tools and accessories like an optional bed?

Not necessarily. You can add extra accessories if you want to, but they are mainly for people who want to achieve the most perfect and professional results.

As far as other tools and accessories go, check out our post on the best metal lathe tools and accessories. Also, see what else our readers are adding to their metal shop.

Best Metal Lathe Final Thoughts

That’s all, I gave it all to you. Now that you know all the details of the best metal lathe for the money should have, selecting the right one is an easier task.

Remember, this is a tool you will use for longer periods of time. Because of that, it is recommended that you pick the option that makes you feel more comfortable.

Comment below if you want to know more or something specific. Well then, see you next time!

Once you’ve purchased your new lathe, it’s time to learn more about the parts of a lathe. And be sure to subscribe to our free newsletter below for more metal lathe guides!

Turn Big, Turn Safe. Welcome to the turning world!