Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

Are you looking for mini lathe tools for your metal lathe machinery? Not sure which ones are useful or whether they’re worth buying?

Getting to a high level of productivity with your metal lathe machine has many factors, like precision and individual skill or how often you work on projects.

However, one of the most important factors in speeding up your metal lathe machinery is the lathe accessories and tools that you’re regularly using.

In this guide, I’ll be recommending 20 of the best mini metal lathe tools that you can get to be quicker, more efficient, and more flexible.

25 Best Mini Metal Lathe Tools and Accessories You’ll Need

Here are the 25 best tools and accessories you can get for your mini metal lathe. I’ll discuss the benefits of using each one so that you can figure out if it’s something you really need.

1) Metal Lathe

The first thing you should look at for home shop work is the metal lathe machine itself. This will be one of, if not the most important metalworking tools you need.

The metal lathe machine will be expensive to buy up front, but you should treat it as a long-term investment that’s essential to projects.

High-quality metal lathe machines will last for many years, and work with the other tools and accessories in this list to help you complete each project.

Metal lathes come in different shapes, sizes, machine power, and specific styles. This is a tool that you should always try out in-store before buying to see if it works for you.

Recommendation – BestEquip 7×14 Mini Metal Lathe

The metal lathe machine I recommend is the BestEquip 7×14, which sits at around $600. It has a high-power variable motor, is easy in operation, and has great safety features.

This makes it a perfect option for beginners who want to get into metalworking without getting the most expensive thing or cheap options that aren’t as safe.

It also has a compound rest that helps change the tool post angle smoothly. Along with the compound rest, it includes a 3-jaw chuck that helps set whatever you’re working on in place.

PRO TIP: While lathes are known primarily for turning and shaping metal, you can use different tools to do undercutting, knurling, facing, boring, drilling, and even cutting.

2) Metal Lathe Jaws

When you put a metal piece into your lathe, it needs to stay in place. While the lathe chuck holds your metal piece, the lathe jaws hold the lathe chuck in place.

It can also be connected to a spindle that’s a tool holder for non-standard-shaped work materials.

Getting sturdy and non-slip lathe jaws is important for home shop work because it moving even a quarter of an inch can ruin the metal piece you’re working on.

These are tools that wear over time, and you should replace them when they do. However, don’t cheap out because they can pose a safety hazard if you don’t use high-quality ones.

Recommendation – WEN LA444 4-inch Jaw Set

The WEN lathe jaws are my recommendation when it comes to getting lathe jaws. These jaws are perfect for holding bowls, spindles, and other unwieldy wood lathe projects.

They feature jaws that can tighten around workpieces from 1.6 to 2.8 inches in size, and the set includes a screw chuck for added support.

They can also spread inside of workpieces with pilot holes ranging from 2 to 3.2 inches.

While they are on the pricier side at $55, they are reliable and have thousands of great customer ratings over on Amazon, so these are a safe bet.

3) Knurling Tool

The knurling tool allows the user to cut a pattern in any metal piece or other material. The advantage of using a knurling tool over doing it by hand is that it’s a lot more accurate.

Mistakes when using a knurling tool are a lot less common than those done by hand, especially when being done by someone not experienced in hand carving, no matter the material.

Recommendation – HFS (R) Adjustable Knurling Tool Holder

This knurling tool holder is made of high-quality #45 carbon steel and can accommodate designs from 0 inches to 2 inches in diameter.

This tool holder is also designed to put less strain on the lathe spindle bearings compared to other tool holder designs, and this model is specifically designed for the mini lathe.

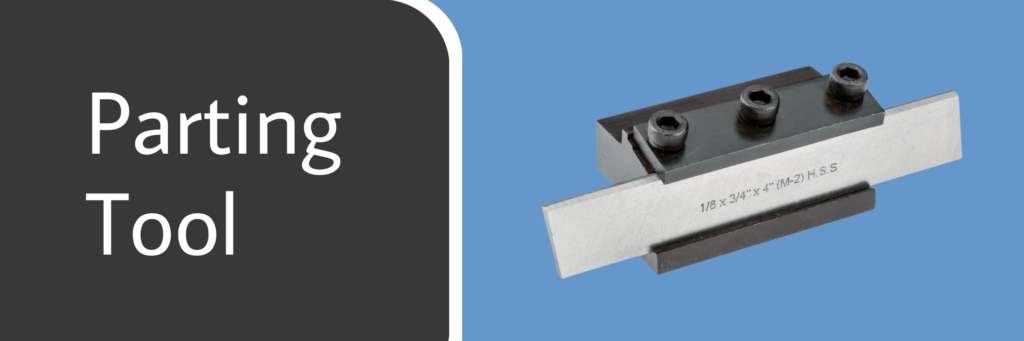

4) Parting Tool

The parting tool holder helps two pieces of metal come apart or away from each other. This is one of the most basic and simple tools on the list.

Recommendation – HHIP 2000-7025

My recommendation for a sturdy parting tool is the HHIP 2000-7025 Parallel-type Cut-Off Blade. One end is beveled while the other is square for different applications.

It’s a finishing tool made of 5% cobalt and made with a parallel style to accommodate parting at different angles and speeds.

5) Quick Change Tool Post

Getting a quick change tool post is important if you want to get a project done quickly because it helps align the tool bit to the lathe centerline.

Usually, you’d have to improvise by stacking shims under the tool bit to get it to match the height of the lathe centerline, but this saves you a lot of time by doing the adjustment more quickly.

Recommendation – 0XA Wedge Type Quick Change Tool Post Set

The best part of the 0XA tool post is that it’s a tool post set, meaning that you get multiple sizes that can all fit with a range of mini metal lathes.

This quick change toolpost is precision engineered and includes tool holders No. 1, 2, 4, 7, and 10.

Customer reviews of this tool post set are good, with no major complaints about functionality.

6) Digital Caliper

A metal lathe is a versatile machine that can bore large holes, smooth out rough edges, or cut metal into pieces. However, there are other applications that need a higher level of precision.

Enter the digital caliper (or digital micrometer), which can help users to see the exact measurements of any part with the press of a button.

You won’t have to bother with trying to peep at an analog one with small markings. A digital micrometer is both more accurate and more convenient to use.

Recommendation – NEIKO 01407A Electronic Digital Caliper

The Neiko caliper has a precise measurement range from 0-6 inches for its jaws and has an accuracy with an allowance of ± 0.01 inches for the dial calipers.

It also comes with four measuring modes which are inside and outside diameter, depth, and step. It also comes with a pre-installed backup battery.

QUICK TIP: When getting replacement batteries for calipers, don’t get those used for hearing aids. Even if they fit in the same compartment, they won’t power the caliper properly.

7) Center Drills

These are stiff, stubby drills that are used to start holes at the end part of any workpiece. Doing this without using a center drill will make the drill wobbly and go off-center.

The standard practice when trying to start a hole is to make a facing cut on the end of the workpiece, and then use the center drill to make pilot holes.

Recommendation – Anytime Tools 5 Center Drill Set

This is one of the best-reviewed center drills on Amazon, and it comes in a full set, with five different tool bits to choose from. Each one has a different diameter.

They come in size 1, 2, 3, 4, and 5 tool bits and are at a 60° angle. It can be found at a value price of only around $16, which is impressive considering it’s a full set.

8) Milling Attachment

While nothing can beat having a standalone dedicated milling machine, some people just want to have an inexpensive way to add limited milling capability to their metal lathes.

The milling attachment adds this functionality to your metal lathe. This makes sense if you don’t want to buy a separate miller which can cost over $1000.

Recommendation – Myford Swivel 2 Way Lathe Milling Vertical Slide

This one from Myford is a great budget milling attachment that you can add to your mini lathe without breaking the bank.

The slots or jaws on the base measure 4.9×3.9 inch per slot for clamping down, and is constructed with mostly metal materials for durability.

9) Lathe Boring Bar

Lathe boring bars can be used to help bore a hole in a piece of metal. These bars are inserted usually after center drilling has already been done.

The boring bar then uses a blade to cut into the piece, but only at the specified diameter and depth it’s created for. This makes it a lot more precise than drilling freehand.

Recommendation – 14 Pieces Lathe Boring Bar Set

This lathe boring bar set has four tool holders and 10 insertion blade pieces included. These boring bars come in different diameters and lengths for varying bore widths and depths.

The bars and their blade pieces are also made of tungsten and quality cemented carbide, which has its own PVD coating. This just means that each blade is durable and will work well.

10) Wrench Set

What is any workshop set up without a good wrench set? It’s one of the most basic and useful sets to have when doing anything workshop related.

This is why you’ll want a wrench set that will have different shapes and sizes for you to make any necessary adjustments to pieces or tool holders.

You’ll also want a set that’s handy and can be easily organized so that it doesn’t interrupt your workflow.

Recommendation – JAEGER 24pc IN/MM TIGHTSPOT Ratcheting Wrench Set

This 24-piece steel alloy master wrench set includes all the wrench sizes you’d need for any project. It also comes packed in an organizer so you don’t have to rummage through a toolbox.

The 7-stage construction JAEGER used to make this wrench set involves drop forging and heat treating, making the steel alloy harder to bend and more durable.

11) Threading Tool

When a piece of metal needs to have screws in it, you’ll need a threading tool to create the threads that a screw can fit in.

Getting a threading tool set will usually include multiple size tools for varying screw sizes. Not all screws are made of the same size, so it’s important to get a set with the most sizes you need.

You’ll also want a tool set that has both right-hand and left-hand threads to support both types of screws.

Recommendation – Lathe Threading Tool SER1010H11+SNR0010K11

This lathe screw threading tool set has 5 pieces of 11ER AG60 inserts and 5 pieces of 11IR AG60 carbide inserts that can do both left and right-hand threads.

This tool makes cutting standard 60° threads for the appropriate screws, either for left or right-hand turning.

12) Faceplate

Every once in a while, you’ll need to use a faceplate instead of a chuck to hold work that can’t fit in any regular-shaped or sized chuck and attach it to a spindle.

The faceplate has the same purpose as a chuck, but not all mini lathes have had it included in the set it comes with for quite some time.

Mounting the faceplate chuck on the spindle can be tricky on some metal lathes, though, because some studs required to mount it may not be provided as well with your lathe.

Recommendation – PSI Woodworking CF3J Lathe Faceplate

This face plate chuck from PSI works well, and there’s an option to buy one with or without a screw chuck in the middle.

It has a three-inch diameter and is made with high-quality steel. Cast iron faceplate chucks also offer good rigidity but they may or may not rust depending on the coating.

This faceplate chuck is handy as a tool holder for small bowl turning because it has machined flats that you can easily grip with a wrench for easy installation and removal.

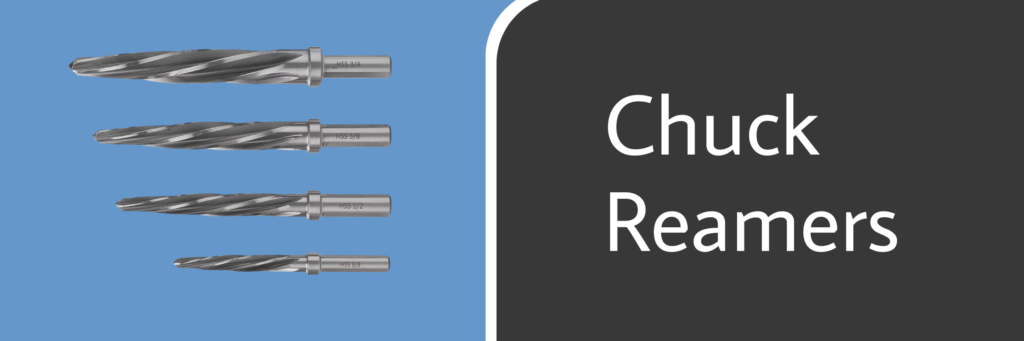

13) Chuck Reamers

Chuck reamers are cutting tools that are handy in making the finishing cut on small diameter holes. Unlike drill bits, they’re designed to make perfectly round holes accurate to 0.001″.

The accuracy level is so high that they’re available in nominal sizes like 1/8″, but are also available in 0.001″ above and below the nominal sizes.

They’re usually attached to the tailstock chuck or a drill press chuck and used similarly to a drill. They can get expensive, so it makes sense to only buy as you need them.

Recommendation – Accusize Industrial Tools 29 Pc Chuck Reamer Set

This chuck reamer set from Accusize includes almost all the tools that you need for any cutting application, as it has shank size options from 1/16″ through 1/2″.

You can also buy variants of the chuck reamer that come in different shank size options, depending on what you need. They are made for right-hand cuts and are made of steel.

14) Live Center

A center is used in the tailstock to support the end of longer workpieces. A mini metal lathe set comes with a dead center, meaning it doesn’t rotate freely with the workpiece.

This causes friction in the material which can lead to overheating. To avoid this, use a live center, which rotates freely in its bearings and rotates with the workpiece material.

Recommendation – Findmall MT2 Medium Duty Live Center

This model from Findmall includes a #2 size morse taper that can be used up to a max of 5000 rpm. It’s made of high-quality hard steel that won’t let impurities into the material.

The small #2 size is also perfect for working on mini metal lathe machines as it fits well. However, you can also get other center sizes if you need them.

15) Steady or Follower Rest

The steady rest is used to support workpieces from tipping or making unnecessary movements when the lathe is spinning the chuck or spindle.

The follower rest is similar, but it moves around with the carriage to provide moving support.

This gives more support for the work material behind the cutting tool compared to the steady rest. However, both will improve the efficiency and quality of your workflow.

Recommendation – Tenfer Woodturning Steady Rest

This rest from Tenfer is easy to install, without the need for extra tools. Each wheel that secures the workpiece can be adjusted individually for maximum precision.

It can accommodate turning pieces from 1/2 inches to 5.5 inches. The wheels themselves are also made of soft materials that conform to the workpiece.

16) Drill Sets

Having a drill set is one of the basic requirements when getting lathe equipment because drilling is one of the main uses of a lathe.

The important thing to remember when choosing drill set to buy is that the drill heads should be made of high-speed steel and not softer carbon alloys.

Spending a bit more when getting a good-quality drill set will save you a lot of headaches in the future, especially if a tool breaks in the middle of a job.

Recommendation – EFFICERE 8-Piece Premium Large Drill Bit Set

This 8-piece set from EFFICERE is a great starting set suitable for a larger project. It comes in 8 sizes, from 9/16th size to a full 1-inch size.

They’re all made of high-quality cobalt and high-speed steel so that the tip won’t bend or warp when used in a drill operation with different types of material.

Take note that this is suitable for use with a larger project. If you’re looking for a smaller drill tip set, there are smaller sizes available.

17) Bench Grinder

Grinding is also another essential part of a lathe job. A 6-inch grinder is perfect to use with a mini lathe for grinding tool bits.

Recommendation – DEWALT Bench Grinder, 6-Inch

The DEWALT bench grinder is a perfect tool for grinding tool bits for any project or job. It has a 5/8 horsepower induction motor that’s made for heavy-duty grinding operations.

It also has a cast iron base that will last for years, and the motor can run at 3,450 rpm for high-speed material removal.

18) Feeler Gauges

Another essential part of any home shop setup is feeler gauges. Feeler gauges are thin, accurately cut steel strips used to measure small gaps between surfaces.

When not in use, each blade folds up into the handle to prevent it from cutting the user. However, it can also be used as a shim if you don’t have a quick change tool post yet.

It can be done by using two pieces or more at the bottom of the cutting tool. Then you can align the cutting tool with the centerline of the lathe.

Recommendation – Hotop 32 Blade Feeler Gauge Set

This set from Hotop features 32-blade feeler gauges in one handle set. They’re individually marked and go from 0.0015 inches to 0.035 inches in width.

Each blade folds neatly into the handy handle to prevent each edge from cutting the user or from bending due to accidental drops because of how thin each blade is.

19) Safety Glasses

The most essential part of any home shop setup is safety equipment. This includes having safety glasses. Most people know to use gloves, but glasses are just as important.

While heavy-duty gloves prevent from accidental drill mistakes or cutting your hands, safety glasses prevent random flying objects like a rogue drill tip from flying into your eye.

Any sharp point is a massive safety hazard for your eyes if it goes flying, especially if you’re standing close to the lathe machine while working.

Recommendation – Dewalt DPG54-1D Safety Glasses

This is a high-quality and protective pair of safety glasses from Dewalt that can come in handy if any accidents on the job mean a sharp point goes flying toward your eyes.

It features a polycarbonate lens, rubber-tipped temples, and a distortion-free lens to complete the convenient, safe, and good-quality requirements for any work tool.

20) Tool Rest Bar

When doing work with any tool like a drill on a lathe, your hands are bound to get tired. The tool rest bar is meant to ease fatigue in your hands.

It will allow you to move your tool across the lathe smoothly while taking away a lot of the tool’s weight away from your hands and arms.

For anyone working long hours with their lathe, the tool rest bar is an essential and necessary piece of equipment that will more than pay for itself.

Recommendation – NAGU Tool Rest Bar

This rest bar from NAGU uses a high-quality hardened steel rod that won’t nick or dent, and will stay smooth after years of use without the need for constant filing.

Some other rest bar brands use rods made of cast iron, but I recommend hardened steel or other alloys for a smoother material that will last quite some time longer.

21) Air Compressor

The air compressor is another common sight in any lathe setup or metal shop. This is because the air compressor is often used to help power the lathe itself.

The only requirement when getting an air compressor for your lathe is that it needs to support the power requirements that your lathe needs.

Recommendation – DEWALT Pancake Air Compressor

The Dewalt Pancake air compressor is one of the best compressors for use with a lathe. This is because it has a 6-gallon capacity and 165 PSI air pressure, which is more than enough.

Another great feature of this air compressor is that it runs relatively quiet for the power it delivers, at 78.5 dBA. This is comfortably below the decibel level that would hurt your ears.

It’s also relatively portable with a carry handle so that you can move it to and from your home shop workspace without much hassle.

22) Grooving Cutter

Many metal pieces require grooves to be cut in them, and this is where the grooving cutter gets its name and use. It can easily make grooves of varying widths and depths.

With a powerful and fast lathe, this grooving cutter will make quick work for an experienced metal worker. For beginners, take your time and practice, the speed will follow.

Recommendation – Amana Tool – 1/2″ Insert Grooving Cutter

This Amana grooving cutter tool measures 1/2 inch and weighs very light at 0.041 ounces. It will mount your lathe easily and give you no headaches or inconveniences.

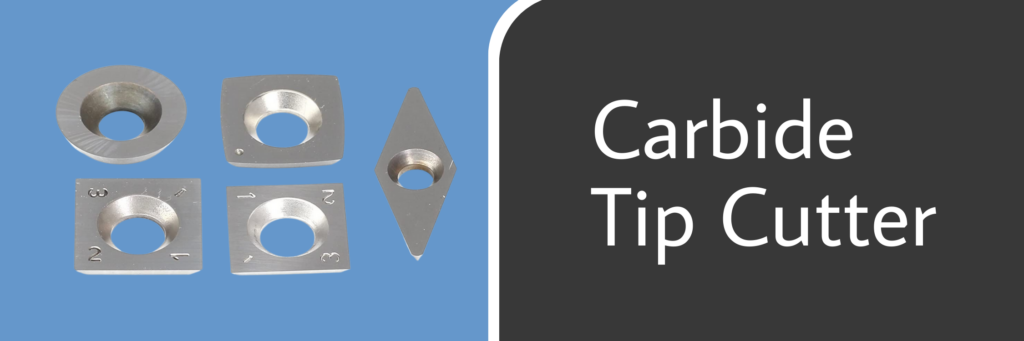

23) Carbide Tip Cutter

Carbide tips are one of the sharpest and most durable points to use in a cutter, which is perfect for metalworking uses, especially with a lathe.

These can be used in conjunction with drills to create accurate holes in any piece you might be working on, whether it be made of metal or wood.

Recommendation – PNBO 20 pc 1/2″ Carbide Tip Tipped Cutter

This carbide set from PNBO includes 10 pieces of size C6 sets and 10 pieces of size C2 sets. The C6 sets are made of machined steel parts while the C2 sets are made of machined iron parts.

Just make sure to use the right type of blade for the hardness of the materials you’ll be using it on or they might wear out too quickly.

24) Scraper

You’ll usually need a scraper when doing the finishing touches on a metal piece. It allows for the metal surface to feel smoother and look better finished overall.

Most novice metal workers tend to leave their project with some marks and blemishes, which can easily be removed or smoothed out using the scraper.

Recommendation – NYKKOLA Razor Blade Scraper

Thie NYKKOLA razor blade scraper is a great tool to use when finishing your project. It has a high grip, a nonslip handle, and a splint made of high-grade aluminum.

It comes with 10 additional blades aside from the one already mounted on the scraper, so that if the first one gets dull, you have a lot of backup blades to easily mount on.

The best part of this scraper is that it doesn’t have to be used only with a lathe. You can use it to scrape off extra wood shavings or remove adhesive stickers from your car’s windshield.

25) Thread Adapter

The chuck on your lathe can hold many different tools. However, these different tool types may not have the same threads and may not be compatible with the chucks.

This is where the thread adapter comes in. It’s a simple adapter that fits one type of thread on one end and another type of thread on the other so that the tool can still be used.

Recommendation – JL-BRAND Thread Chuck Insert/Adaptor

There are many different variations and thread types available with this JL-Brand product. There are right and left-hand thread variants and different thread sizes.

This means finding the right thread size for your tool and lathe won’t be difficult. Just make sure to check which side is “male” or “female.”

The male side is where the tool will be screwed in, while the female side will go into the lathe.

Types of Metal Lathe Tools

There are nine different types of tools that are used in a lathe. Here are the nine types:

- Turning tool: removes small pieces from the workpiece

- Boring Bar: makes an existing hole bigger

- Chamfering Tool: creates a bevel or chamfer on the workpiece

- Parting Tool: cuts work pieces into two or more pieces

- Knurling Tool: creates a pattern on a rounded surface

- Thread Cutting Tool: to cut threads in a piece for screws

- Facing Tool: to cut a piece perpendicular to its rotational axis

- Grooving Tool: to engrave or cut a specific shape into a surface

- Forming Tool: imparts a specific shape or profile onto a piece

Each one has a distinct use case in a lathe, and whether they use a drill, point, tip, or are circular or square, they each serve a purpose.

Characteristics to Consider When Choosing Mini Lathe Tools

There are a few characteristics and factors you should consider before you choose the lathe tools you’ll buy. These include the price, materials, and completeness.

Price

The first thing you should always consider before buying anything is how much it costs. While it can be tempting to always buy the highest-end product you see, it isn’t always practical.

When to Get High-End Items

In some cases, getting a high-quality tool is ideal. For example, when buying the lathe itself, you should get a high-quality one because you’ll be using it for years until it needs repair.

In that case, if you buy the cheapest option that isn’t the best quality, you might end up replacing it more and having headaches with your projects.

When to Get Cheaper Items

On the other hand, if you want to buy a chuck set and know that they’re a consumable product that you’ll eventually have to replace anyway, you can save money on it.

One thing you should never do is overspend on your budget. While you should maximize it, you’ve set a budget for a good reason.

Materials

The next consideration you should make is which materials were used in the tools you want to buy. Some materials are better for specific use cases only.

For example, you should always pick drill bits that are constructed with high-speed steel. While they can be a bit more expensive, you can be assured they won’t bend or break.

Imagine buying a cheaper set and it bending while you’re deep into working on your latest project. The savings aren’t worth the hassle or headache.

The best thing to do is do your research before buying any tool, especially in the customer reviews section. That’s the best indicator of a good quality product.

Completeness

The final factor that you should consider when picking the right tool for your lathe is if the set you’re buying includes all the sizes or variations you need.

For things like chuck sets or drill bit sets, there are different measurements and variations to choose from because of the many pieces that you can work on.

For example, if you’re working on a piece that needs screws that can turn both right and left hands, you’ll want a threading tool set that supports both.

You don’t want to buy something just to get home and realize that it doesn’t fit the requirements you have for a specific job or piece.

Therefore, the most important thing to remember is to know what you need for your project and read the product descriptions thoroughly.

Frequently Asked Questions

Now that you know more about lathe tools, which are the best, and what to consider before buying them, you might still have more questions related to them.

I’ve answered the most commonly asked questions below.

Can Metal Lathe Tools and Accessories Be Used With Any Type of Metal Lathe Machine?

While most tools can work on any lathe, there are some tools that are made for a specific size of lathe. Make sure to take note of the product description before buying the tool.

For example, a steady rest is made for a specific height and length of lathe, so you should buy a rest that fits the specific measurements of your lathe machinery.

Other tools like the caliper, wrench sets or feeler gauge sets are universal and will work with anything, so you shouldn’t worry about them.

Are There Any Safety Precautions I Should Take When Using Metal Lathe Tools and Accessories?

The first precaution I would recommend is to use the proper protective equipment like gloves, safety goggles, and protective clothing like an apron.

Using this equipment is crucial in staying safe when doing work. The gloves and apron will prevent you from receiving accidental scratches and cuts on your hands and body.

Meanwhile, the safety goggles can keep fine materials, metal dust, or rogue metal shards from ricocheting into your eyes and possibly blinding you.

Some additional advice I can give to stay safe when working on your lathe is to take regular 15-minute breaks every hour to hour and a half.

This will prevent you from making mistakes due to fatigue and ultimately result in you having higher quality outputs for your project.

What is the Best Steel for Lathe Tools?

The best metal for lathe tools like drills is high-speed steel. The advantage of this metal is that it’s specifically designed for metalworking cases.

It can be used with a high rpm lathe without distorting, bending, or breaking, unlike other alloys like carbon steel. Those are much softer and have a higher chance of failure.

However, for other tools that aren’t mainly used for making a constant, high-stress impact with the piece like a caliper, the materials used aren’t as big of a factor.

Conclusion

After reading this full and extensive guide to the best lathe tools you can find, I hope that you’re more knowledgeable about them and can make the best purchase decision.

Whether you’re getting a chuck, drill, caliper, or the lathe itself, the important thing to remember is to check the reviews and pick one based on what you need.

Don’t go out of your budget, but maximize it to its fullest extent. Don’t cheap out on the materials that will be used in high-stress situations, but don’t overspend, either.

Hopefully, these tips and advice will help you out in picking out the best tools and accessories for your next home lathe setup.

You might also like our list of what our readers are adding to their metal shop. These are especially great items for new metal turners.