Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

Last Updated on April 22, 2023 by Charles Wilson

If there’s one machine you need in your workbench, it’s a metal lathe.

Whether you’re just starting out as a hobbyist or you plan to create a business in metal crafting, using a lathe is a great way to start.

In this article, I’ll walk you through what a mini metal lathe is and how you can use it in various applications.

Key Takeaways

- A mini metal lathe machine is a stationary cutting tool that shapes and cuts objects.

- Different cutting tools are used to drill, cut, sand, and deform the workpiece to achieve different results.

- An operator can use a lathe to make screws, pins, bowls, pens, and many other small objects.

- Although a metal lathe is primarily used to shape metal, it can also be used for turning wood, plastic, glass, and various other materials.

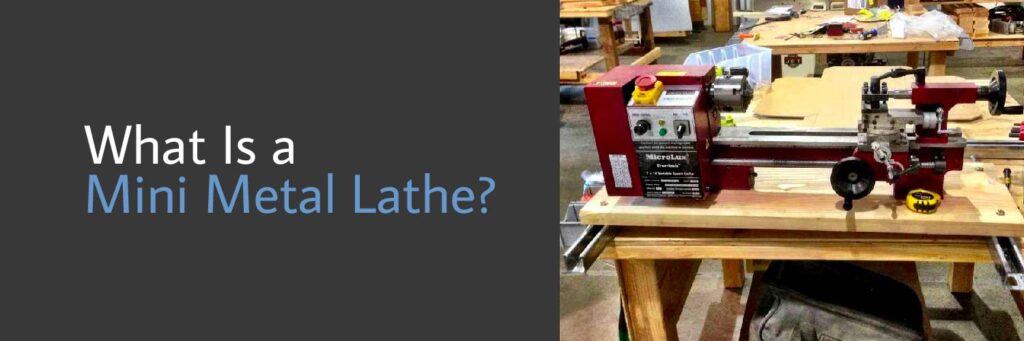

What Is a Mini Metal Lathe?

In a nutshell, a mini metal lathe is a lathe machine used for metal crafting and woodworking.

Although most lathe machines are intended for professional manufacturing, it’s easy to get into them for home or hobby use!

It’s best for crafting small parts for robotics, jewelry, or any hobby project.

Think of a mini lathe machine as a miniature version of an industrial-sized lathe. It can do whatever its big brother can do.

Many crafters turn to mini lathe machines because you don’t need a big floor space to get started. I personally just plop it on a workbench.

What’s great about mini lathe machines is that they’re generally more affordable than regular lathe machines.

How Does a Mini Metal Lathe Work?

A mini metal lathe machine uses a rotating drive that turns a material on its axis to cut various shapes.

To find out how a mini lathe works, we have to break down the different components of the machine.

Your standard mini lathe machine is composed of various parts:

Tool Post

This device is where you mount the cutting tools you’ll use to carve the material you’re going to be working with.

The tool post is placed on two slides: the cross slide and the top slide.

Slides

The cross slide moves along the horizontal axis, and the top slide moves on the vertical axis.

You can control the slides via hand wheels located on the lateral side of the slides.

Since the top slide works on the vertical axis, you can also shift the post diagonally relative to the axis of rotation.

Cross slides, on the other hand, are mounted on the main slide or the carriage. It moves parallel to the workpiece and spans the whole length of the work area.

The carriage can be operated using the main hand wheel that is attached to the lead screw.

Motor

Of course, a lathe cannot work without a motor.

The motor of a mini lathe can be controlled using two knobs or switches on the front panel, which allows you to adjust the direction of the rotation.

By the left of the motor are the gears.

Self-centering Chuck

This device is where you clamp the piece you’ll be working on onto the metal lathe.

Feed Handle

This part connects the motor and the lead screw. A feed handle automatically moves the carriage and the cutting tool along the work area.

Tailstock

A tailstock allows you to attach another chuck for drilling operations or inputting a dead center, a device used to reduce chatter in longer workspaces.

How to Use a Mini Metal Lathe: Step-by-Step

The beauty of a mini metal lathe machine is that it can be used for a wide range of projects.

You can use a mini lathe to cut, drill, sand, knurl, and perform other operations — basically, a metal lathe shapes and curves metal.

It might take us all day just to list how to use a lathe in every scenario.

If you’re a first-metal lathe user, don’t be intimidated. There are several beginner-friendly and straightforward projects you can try out!

For this guide, I’ll give you a brief rundown on how to operate a mini lathe to give you a general idea of how to use it:

1: Set-up

First, you’ll need to set up your workstation according to your project.

Mount your mini metal lathe machine on a sturdy work table or pedestal. Place your workpiece into the headstock of the mini lathe using the self-centering chuck.

Select the direction of the rotation and turn on the mini lathe.

2: First Pass

Before starting your project, ensure you wear the appropriate attire and PROTECTIVE GEAR.

Set the lathe RPM you want for this project and rotate accordingly.

Move your tool post slowly towards the rotating workpiece. Control the carriage as needed to operate the cutting tool depending on the method of your project.

Slowly shape the workpiece by scraping off materials. Continue until your workpiece starts to take shape.

3: Wrap Up

Afterward, turn off the mini lathe once you finish your first light pass. Turn it on again and keep working on the piece until you’ve done all the passes with each tool.

Different kinds of cutting tools are used for different operations. Maneuver each tool until you’ve achieved your desired results.

Shape the workpiece according to your project output, whether it’s a metal ring, a metal mallet, or a key chain.

Depending on the project, there are several methods you can do to complete it: threading, deforming, parting, etc. Each process can give various results.

Once you’ve run through all the necessary tools, turn the machine off.

Voilà! You’re done.

Frequently Asked Questions

Here are some commonly asked questions about metal lathe machines that can help you:

How to Choose a Mini Metal Lathe?

If you’re interested in buying a lathe, there are some things you need to consider to get the best value for your money.

Here’s what you need to look for in a mini metal lathe machine:

- Good condition

- Durability

- Stability during operation

- Ease of use

Look for a reputable mini lathe seller or a trustworthy brand offering HIGH-QUALITY lathe products.

Here’s a more comprehensive buying guide for mini metal lathes.

Note that mini lathes may not have the same level of accuracy compared to industrial-grade lathes. The better quality lathe you purchase, the better outputs you can produce.

When Should I Use a Mini Metal Lathe?

This lathe works best when you’re shaping cylindrical or tapered cylinders. Because of its miniature size, you can also use it for micro projects.

You can use a mini metal lathe machine to make special parts fitted for bigger equipment.

If you’re a bit more experimental, you can even craft metal pieces that are useful on their own.

Final Thoughts

From drilling to sanding, a mini lathe machine is a versatile tool used by both hobbyists and manufacturers.

If you want to get started on your metalworking journey, knowing how to operate a mini lathe is a MUST.

In this article, I discussed what a mini metal lathe is and how you can use it for various projects. Hopefully, you’ve learned a thing or two about how mini lathes work. Remember, you don’t have to be an expert right away! Hone your skills and check out other metal projects online for inspiration.