Disclaimer: As an Amazon affiliate, I may earn a small percentage from qualifying purchases. This is at no extra cost to you. Learn more here.

Last Updated on January 23, 2025 by Larry Edwards

The manufacturing industry would never be the same without milling machines. After all, it’s become a superpower machine tool that can cut and shape the toughest metals!

But did you know that a milling machine is more than just a nifty cutting tool?

That’s right — there are different types of milling machines, each having its unique use.

In this article, I’ll give you a general idea of the milling machine definition and how and what it is used for.

Key Takeaways

- Milling machines are a type of production machine that can perform many functions, such as face milling, cutting, shaping, and drilling different types of materials.

- There are different types of milling machines depending on your intended use.

- Milling machines require preventive maintenance to avoid unnecessary breakage that can slow down work.

What Is a Milling Machine Used For?

The manufacturing industry knows milling machines are a beast when it comes to performance.

It’s frequently used in a production setting, and it’s become a tried and tested cutting tool that various industries can’t live without.

Briefly, milling machines have sharp milling cutters that can cut through almost all sorts of materials at high speed within their tool axis.

It performs various activities like gang milling, face milling, and more!

Not only that, but it can also work on irregular surfaces so you can transform them to your desired shape.

The entire process is quick — easily cutting and shaping at precise tolerances.

But besides cutting edges and flattening contoured surfaces, did you know milling machines have other uses?

In fact, it can be used to shape and mold materials, make slots, and even drill!

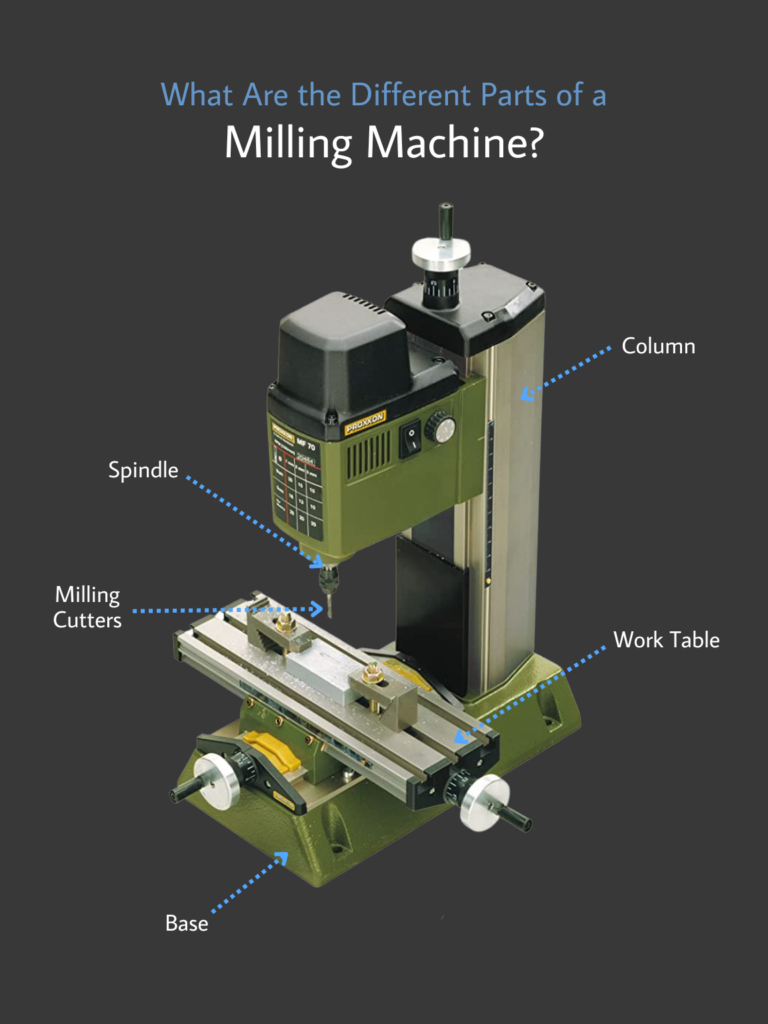

What Are the Different Parts of a Milling Machine

Milling machines are made of different parts, each of which plays an important role in the milling process.

I’ve listed some of the essential parts of the machine which are vital in the milling operation.

Let’s look at each of them and learn how they work:

Milling Machine Base

Milling machines are so big they need to be supported by a strong and durable base.

For industrial machines, like milling machines, the base means everything to the whole milling operation. It ensures the machine doesn’t wobble, nor will it be at risk of falling.

Just imagine the workplace hazard you’d face if your machine topples over!

To avoid this problem, I always ask what the base of the machine is made of.

In general, I always go for machines made of cast iron because I know they’re highly durable and offer great support.

Column

Consider the column to be the powerhouse of the milling machine. It’s typically where you can find the motor that sets the gears in motion.

A good column should protect the machine’s motors, ensuring a smooth milling operation throughout the whole process.

In other milling machines, you might also find the controls on the machine’s column. This design is perfect because everything I need can be found in one place.

Some machines would have motors and controls on the milling head, which is also okay.

Work Table

The work table plays an important part in keeping objects in place in the milling machine. Its main purpose is to securely hold down your piece of work during the milling operation.

A reliable work table is key to accurate and precise cuts each time. It leaves no room for error and ensures the milling cutter goes through the right side each time.

Some milling machines sport a rotary table, which makes cutting and shaping cylindrical objects much easier.

You no longer have to manually hold your piece of work, which is often where the workplace hazard begins.

Milling Cutters

The main event of milling machines is always the milling cutters. You generally want your milling cutter to be sharp, smooth, and precise.

Do note that finding the right type of milling cutter and feed rate for a specific piece of work is vital.

That’s because it helps prolong the tool life of your cutter and provides the best surface finish, even on irregular surfaces!

End mills, for example, are the type of cutter you need for cutting slots, punching holes, face milling, or shaping your work.

An end mill typically looks like the end of a drill head, but this one has a wide range of functions.

On the other hand, formed milling cutters are perfect for creating round edges on a flat surface. It can also perform a variety of functions, similar to end mills.

Milling Spindle

The milling spindle is often an overlooked part of the milling machine when it should be the show’s superstar.

We’re less familiar with the fact that spindles rotate. The direction could vary, depending on the spindle axis — horizontal or vertical, depending on the machine.

The spindle is in charge of sending power to the milling cutter and rotates it based on the direction of the machine.

Frequently Asked Questions

Before I leave you with my parting words, let me answer some of the FAQs I always get about milling machines.

These will help you understand milling machines better and how you can effectively use them:

Are There Different Types of Milling Machines?

There are different types of machines depending on your intended use.

I’ve listed some below, so you can learn how each performs in a milling operation:

CNC milling machines

CNC stands for “Computer Numerical Control.” As its name suggests, CNC milling machines are completely computerized.

The beauty of the CNC machine is that it hardly leaves room for error. Many people prefer CNC control machines because they provide higher accuracy and precision at high speed.

Just input the specs on this machining center, and you’re all set! Some even feature an automatic tool change function, which provides greater convenience.

However, note that a computer numerical control machine is more expensive than your manual milling machines.

Column milling machines

One of the common types of machines you’ll see in milling operations is the column milling machine.

It’s perhaps the simplest type of milling machine out there — perfect for everyday use and only for a simple milling operation.

Horizontal milling machines

If you’re looking for one of the sturdiest and most versatile milling machines, I recommend horizontal milling machines.

Many prefer working with a horizontal milling machine because it can move in almost all directions.

The horizontal spindle and table are always parallel, making it the perfect machine to cut cylindrical and flat surfaces.

Horizontal mills are perfect to have in the workplace because of their many uses in the milling operation. It’s a versatile machine that is packed with enough power.

Manual milling machines

Manual milling machines are a general classification of milling machines.

As its name suggests, a manual milling machine is typically operated by hand. It can perform a wide range of functions, depending on your machine.

I recommend this milling machine for small workplaces that don’t require mass production.

Cutting and shaping contoured surfaces might be a little labor intensive, but at least you have a wide degree of control to get things right.

Universal milling machines

When cutting solid materials, you best believe that universal milling machines can do the job. Regardless of how thick the material is, it can be cut and shaped like butter.

One of the things I love about a universal milling machine is that it has an indexing head and can swivel up to 45 degrees.

This allows you to work on every angle and not just on flat surfaces!

It can travel vertically and horizontally across the X, Y, and Z-axis, making it more versatile than most milling machines.

Vertical milling machines

Vertical mills are perfect for cutting edges, slots, grooves, and more!

Vertical machining centers usually sport a fixed X and Y axis, and the vertical spindle can only move up and down on the bed mills.

Thanks to its impeccable precision, a vertical milling machine leaves no room for error during the milling operation.

How to Maintain a Milling Machine

Milling machines work hard once they’re powered on. Even after several hours of operation, they remain as powerful and functional as ever.

But over time, milling machines can experience work slowdowns and even production flaws. This will lead to a chain reaction of slower work productivity and even delays.

No business wants this — especially if it can be avoided in the first place just by maintaining the milling machine.

I’ve listed some tips to help you maintain your milling machine without costing you a fortune:

Inspect

Before you start your day and power on your machining operations, inspect your milling machine first.

Doing daily inspections helps you spot any issues or defects on the machine, even before the problem worsens.

Plus, you can remove material that got stuck in your previous work.

Lubricate

A great way to keep your milling machine running smoothly is to keep its gears well-lubricated.

Doing this keeps your machine running for hours without experiencing any work slowdowns.

However, this doesn’t mean you should lubricate your milling machine daily. Always check the instructions on how often you should be lubricating your machine and by how much.

Clean

I highly recommend that you clean your milling machine for any loose debris after you use it. Sometimes, your milling machine needs a good cleaning to get it back in good shape.

Remember, a lot of loose material can get in the crooks and crannies of your milling machine.

This might not seem like a big deal now, but once all these loose materials pile up, a bigger problem arises.

Service

A simple band-aid solution can’t fix any issues with your milling machine. Remember, milling machines are heavy-duty pieces of equipment that require professional servicing.

If you notice any problem with your milling machine, I recommend you already have it serviced and leave the professionals to their job.

They’ll know the issues and the best way to fix them.

Are Milling Machines Expensive?

Yes, milling machines are quite expensive, and buying them is no joke. You have to set aside a budget for it and know exactly what kind of milling machine you plan to buy.

One of the major reasons why milling machines are so expensive is because of their build. The material milling machines are usually made of is tough, durable, and stable.

Also, milling machines go through a lot when they are built. Safety standards must be complied with, and all equipment parts must be installed properly.

If you’re looking for a good milling machine to invest in, we highly recommend choosing from a reputable brand.

You’re more or less secure knowing their milling machine is worth the price tag.

Final Thoughts

As a super powerful tool, the milling machine is one of the reasons why the manufacturing industry remains afloat.

Since its humble beginnings and even until now, we have seen a lot of uses for milling machines, which makes our life a lot better.

I hope I’ve fed your curiosity and answered the question, “What is Milling Machine?”